With the Spreadsheets you will be able to obtain a technical estimate of equipment such as: pumps, compressors, air coolers, shell and tube heat exchangers, pressure separating vessels, among other main equipment important for the engineer in training.

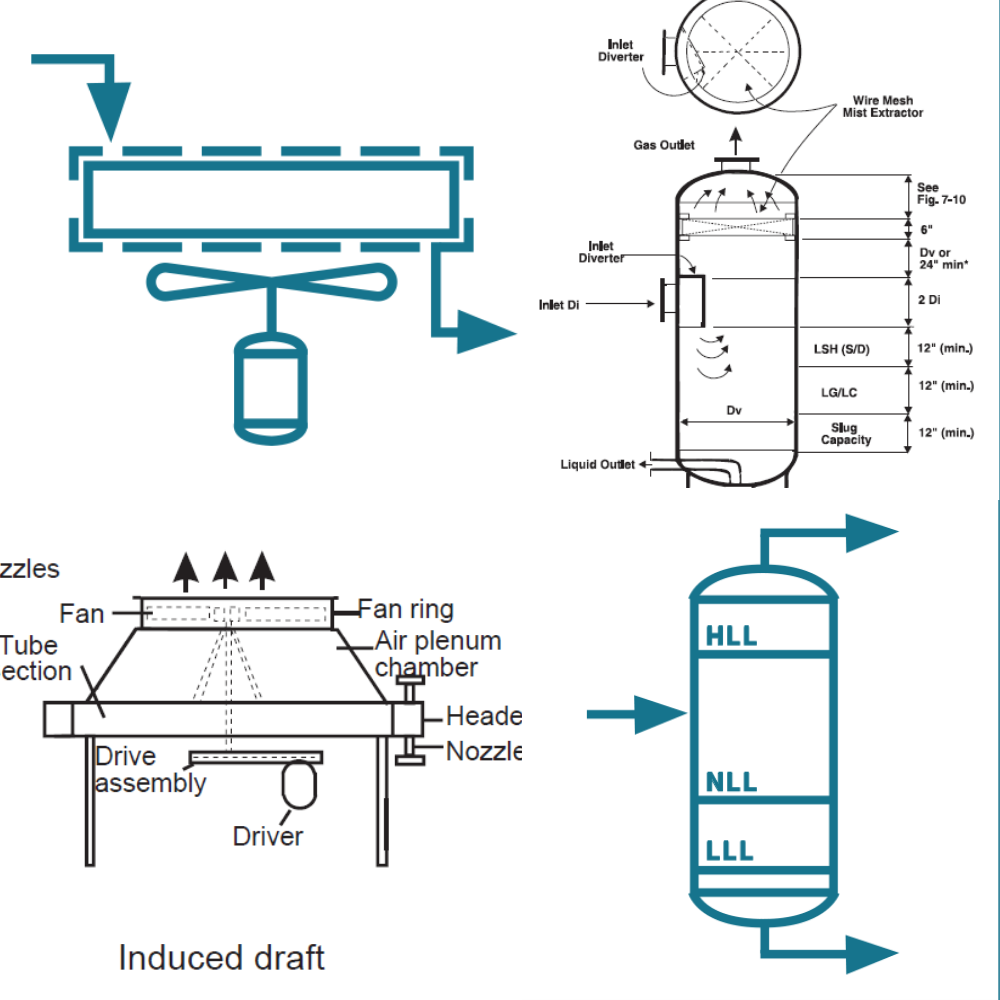

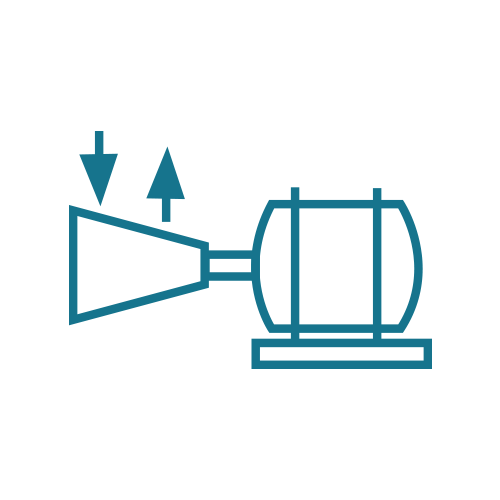

The Spreadsheet helps to make a preliminary design of an Air Cooler: Size and Geometry. A reasonable estimate of an air cooler can be found from the following steps:

- Select a value of the global heat transfer coefficient, Uo, depending on the process fluid.

- Estimate the air outlet temperature (t2).

- Calculate the arrangement of the tubes and the fan power

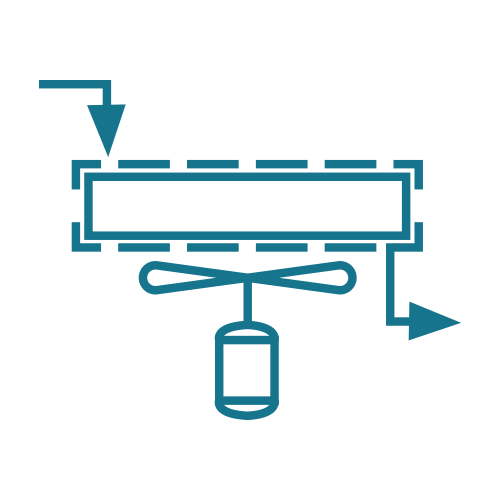

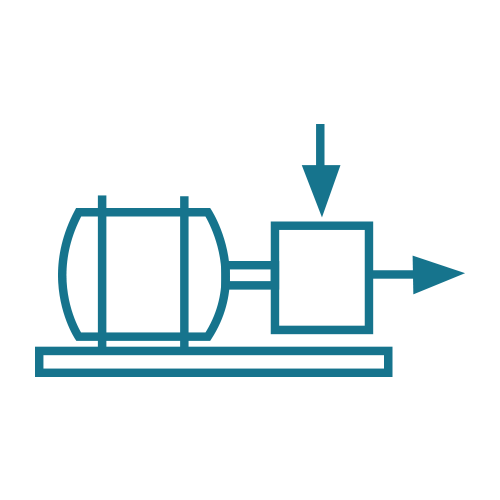

With the spreadsheet you can determine important information for the sizing of a pump such as:

- Shutoff pressure

- Brake horse power

- Net positive suction head

Additionally, hydraulic calculations can be obtained in the suction and discharge lines, the results of which are automatically fed into the pump’s own calculations.

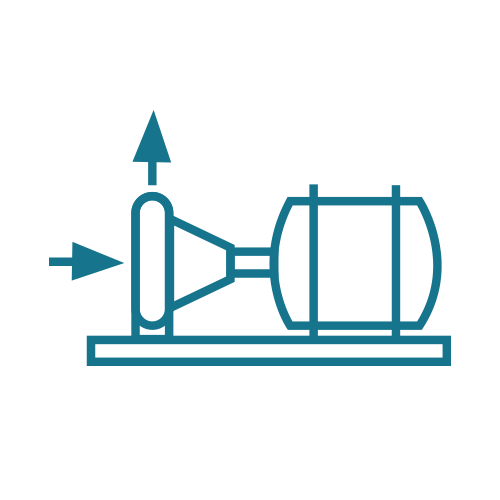

Heat transfer is defined as the interaction between fluids or materials due to a temperature gradient between them. With this spreadsheet it will be possible to carry out a pre-sizing of heat exchangers in which there is no phase change. The main parameters that can be obtained in this spreadsheet are listed below.

- Heat balance & LMTD calculations (calculated duty, LMTD, etc)

- Heat transfer coefficients (calculations tube wall heat transfer coefficient (ht), overall heat transfer coefficient (Uo), etc)

- Pressure drop calculations (nozzle internal diameter, fluid velocity, etc)

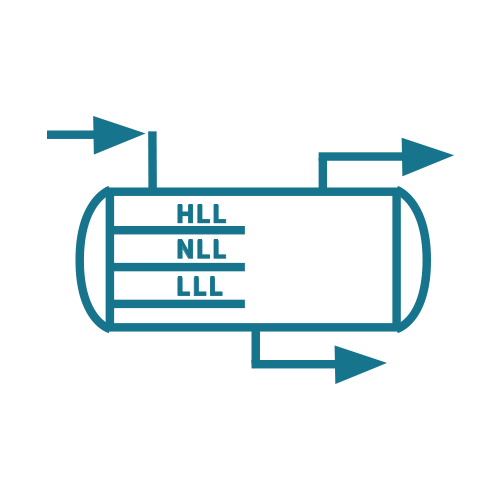

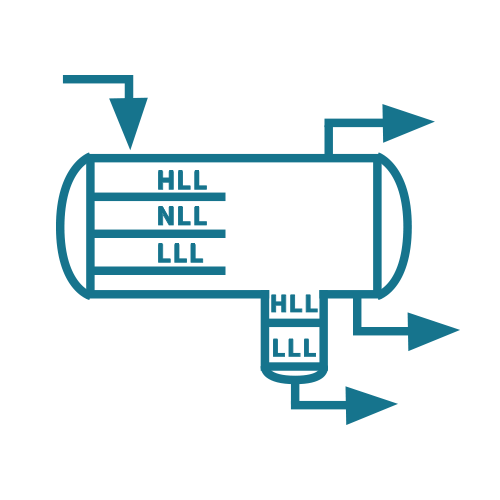

With the spreadsheet you can determine important information for the sizing of a Horizontal 2 Phase Separator such as:

- Minimum vessel diameter calculation

- Estimated liquid volume (By Residence Time)

- Liquid levels alarms

- Process nozzle sizing

- Vessel sketch

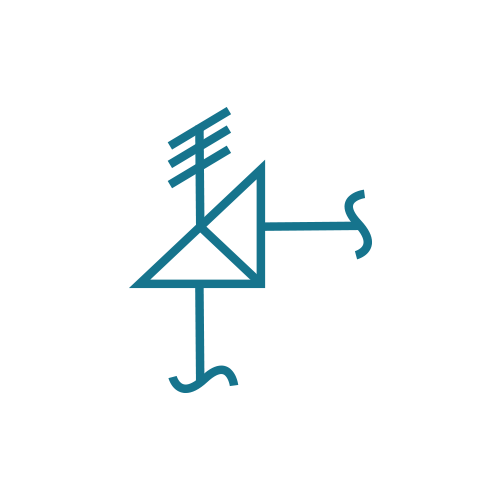

With the spreadsheet it is possible to determine important information for the sizing of a centrifugal compressor such as:

- Required compression stages

- Compression ratio by stage

- Centrifugal compressor horsepower (by isentropic & polytropic calculations)

With the spreadsheet you can determine important information for the sizing of a Reciprocating Compressor such as:

- Required compression stages

- Compression ratio by stage

- Reciprocant compressor horsepower (by simple calculations & Correction of Physical Properties in each Stage (See Charts on Section 23 of GPSA)

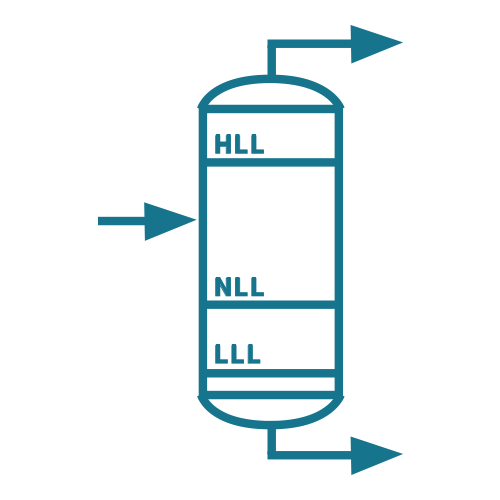

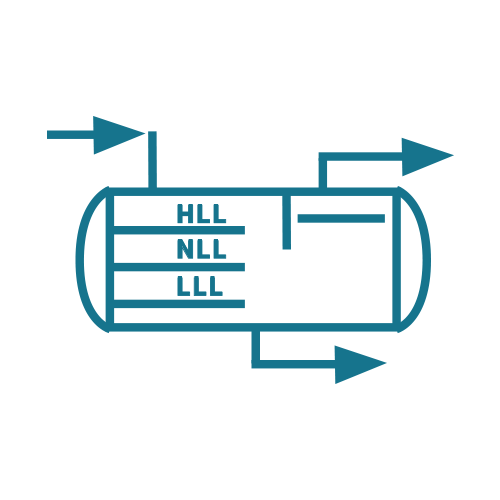

With the spreadsheet you can determine important information for the sizing of a Vertical 2 Phase Separator such as:

- Minimum vessel diameter calculation

- Vessel length calculation

- Liquid levels alarms

- Process nozzle sizing

- Vessel sketch

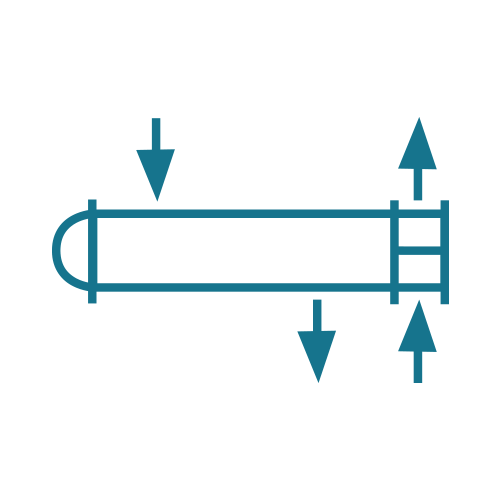

With the spreadsheet you can determine important information for the sizing of a Vertical 3 Phase Separator such as:

- Minimum vessel diameter calculation

- Method for estimating the separation coefficient

- Minimum levels suggested

- Vessel length calculation

- Liquid levels alarms

- Process nozzle sizing

- Vessel sketch

The dimensions of the tanks shown in the calculations are taken from the API STANDARD 650 “Welded Steel Tanks for Oil Storage” (Tables A-1b / A-3b – Typical Sizes and Corresponding Nominal Capacities).

The dimensions of the tanks shown in the calculations are taken from the API STANDARD 650 “Welded Steel Tanks for Oil Storage” (Tables A-1b / A-3b – Typical Sizes and Corresponding Nominal Capacities).

The calculations are based on API 521 (API Recommended Practices) standards. With the spreadsheet, the following parameters can be obtained:

- Required dropout velocity

- Estimated liquid volume (by residence time)

- Vessel dimensions

- Process nozzle sizing

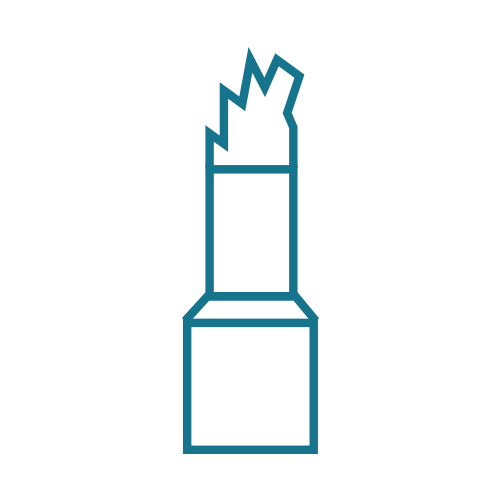

The spreadsheet will allow a pre-sizing of flares, based on the standards and procedures API RP 521 and the Gas Processor Suppliers Association (GPSA) Engineering Handbook. With the spreadsheet, the following parameters can be obtained:

- Sizing of the Burner Nozzle

- Amount of Steam

- Radiation calculations

- Flame length and distortion

- Height of the burner:

With the spreadsheet you can determine the following parameters related to fire & radiation calculations

Radiation:

Product leak rate

Flame length

Lateral danger range where 50% of fatalities occur, etc.

BLEVE explosions

Maximum Fireball Diameter

Fireball Duration

Average Radiation Intensity at the Center of the Fireball

Average Radiation Intensity at Floor Level

Incidence Angle to Study Point, etc.

FIRE POOL

Total Radiated Heat

Fraction of Transmitted Combustion Energy

Relationship between Flame Height and Fire Pool Diameter

Normalized Burn Rate, etc

With the spreadsheet it will be possible to obtain all the necessary parameters to validate a certain diameter selected according to the flow carried by the pipe. Below are some items that can be obtained while using the calculation tool:

Flow Characteristic

Equivalent Length

Actual Velocity

Frictional Pressure Drop

Total Pressure Drop