ENGINEERING EARLY STAGE

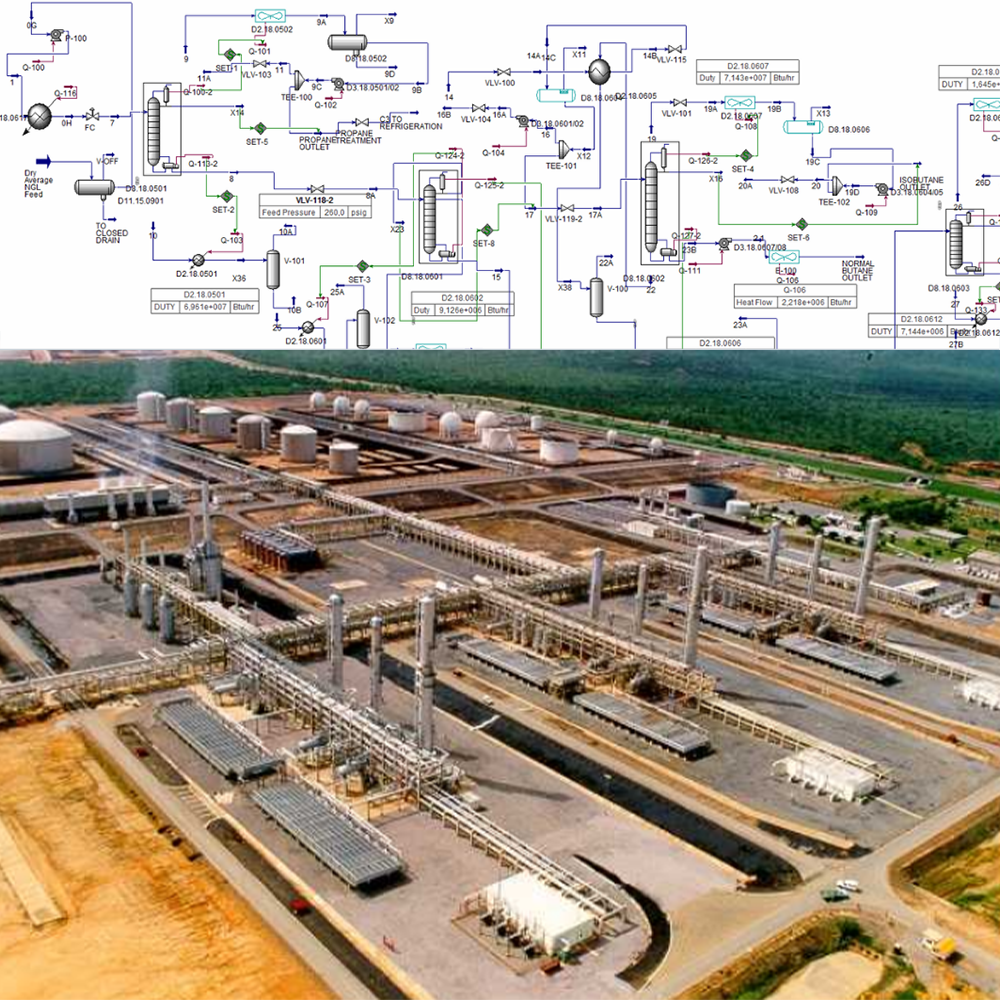

GAS PROCESS manages projects from the early stages of engineering, using visualization process schemes are technically and economically adapted to your business to target opportunities for increased efficiencies and growth. With our technology and design experience, we guide your projects; based on our engineering expertise and will always comply with and exceed international standards of quality, safety, health, and the environment in each of the project’s phases.

Our work is developed with high efficiency and quality in mind. All of our engineering products are documented and established in the visualization, conceptualization, basic phases, and FEED phases which are particularly focused on the development of the basic documentation for bidding the Execution Phase Contracts (EPC, EPCI).

Below is shown the typical documentation list (minimum) developed by GAS PROCESS in each engineering step.

GAS PROCESS develops these services in an important variety of energy sectors, among which it is worth highlighting the Gas Processing Plants, Oil Refineries, Chemical and Petrochemical Plants, Combined Cycles, Biomass Plants, among other facilities. For this, we have calculation tools and engineering simulators to facilitate the development of each of the projects.

Investment Valuation and Feasibility Studies (FEED / FEL).

- Determination of CAPEX.

- Studies of Operating Costs of Process Plants (OPEX).

Conceptual Engineering:

- Definition of the process at PFD level

- Preliminary balance of material and energy

- Definition of the main equipment and analysis of its availability in the market

- Basic definition of the project at an electrical and instrumentation level

- Fitting of the preliminary implantation in the area planned for it

- Identification of the necessary services

- Preliminary project planning

- Preliminary cost

Basic engineering:

- Complete development of the unit’s process engineering, Process flow diagrams (PFD’s), Diagrams of piping and instrumentation (P&ID’s), Lists and data sheets of equipment, Design and specification of equipment, pressure vessels, and storage tanks, Specification of dynamic equipment, Lists and data sheets of valves and instruments, Sizing and specification of control and safety valves

- Preliminary development of the project in the rest of the engineering disciplines

- Process simulations.

- Basic design of process equipment.

- Studies of technical and economic feasibility of process and operation modifications.

- Analysis of production processes: Identification and elaboration of proposals to eliminate bottlenecks

- Revamping studies of existing units

- Preparation of monitoring programs for process and production conditions

- Execution of test-run in production units

- Preparation of operation manuals

- Studies of validity/verification of torch systems

- Simulation and performance/efficiency studies or identification of problems in specific equipment: heat exchangers, air coolers, pumps, compressors, piping systems, reactors, distillation columns, among others.